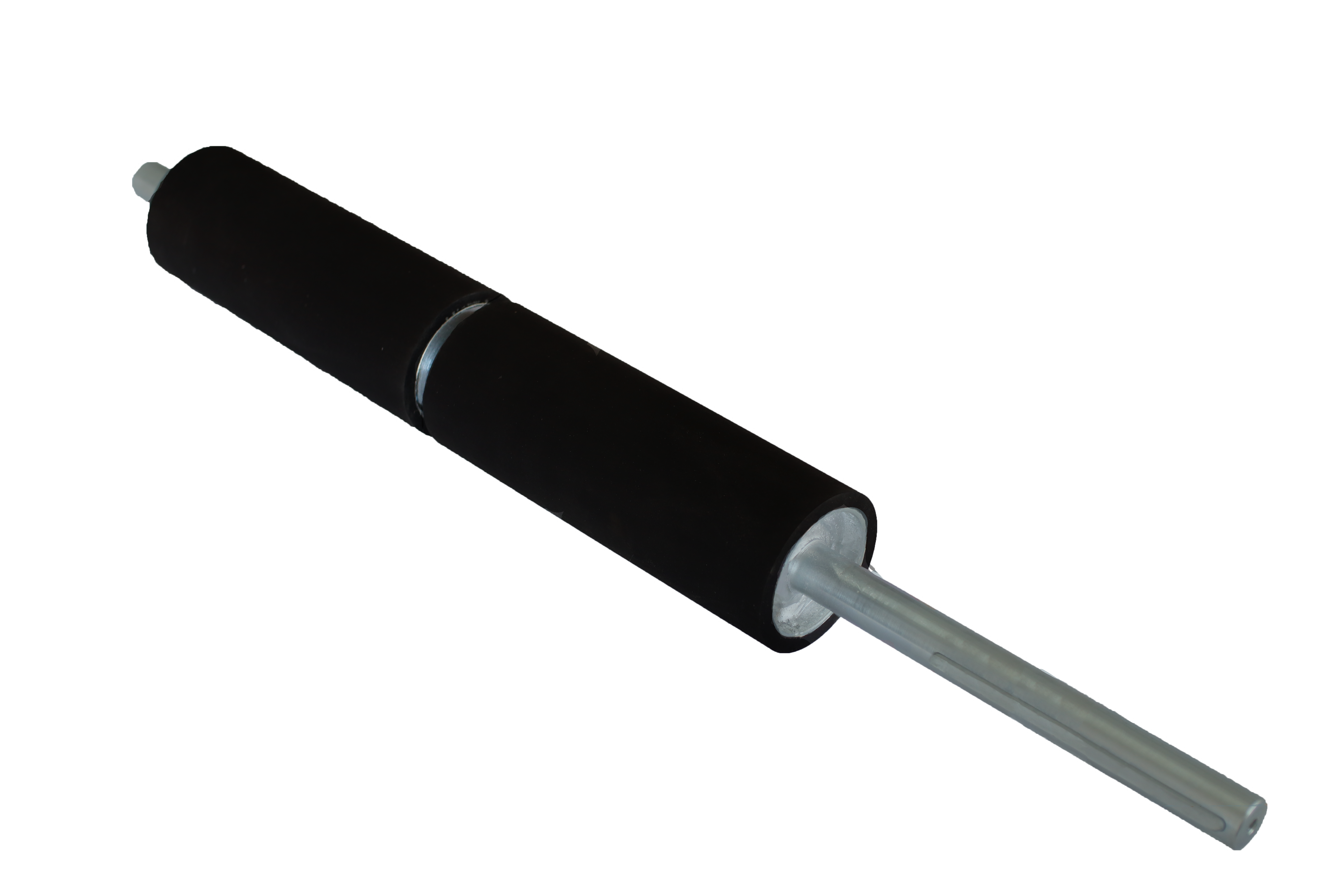

Roller/Shaft

Designed to transmit rotation and torque to the conveyor belt.

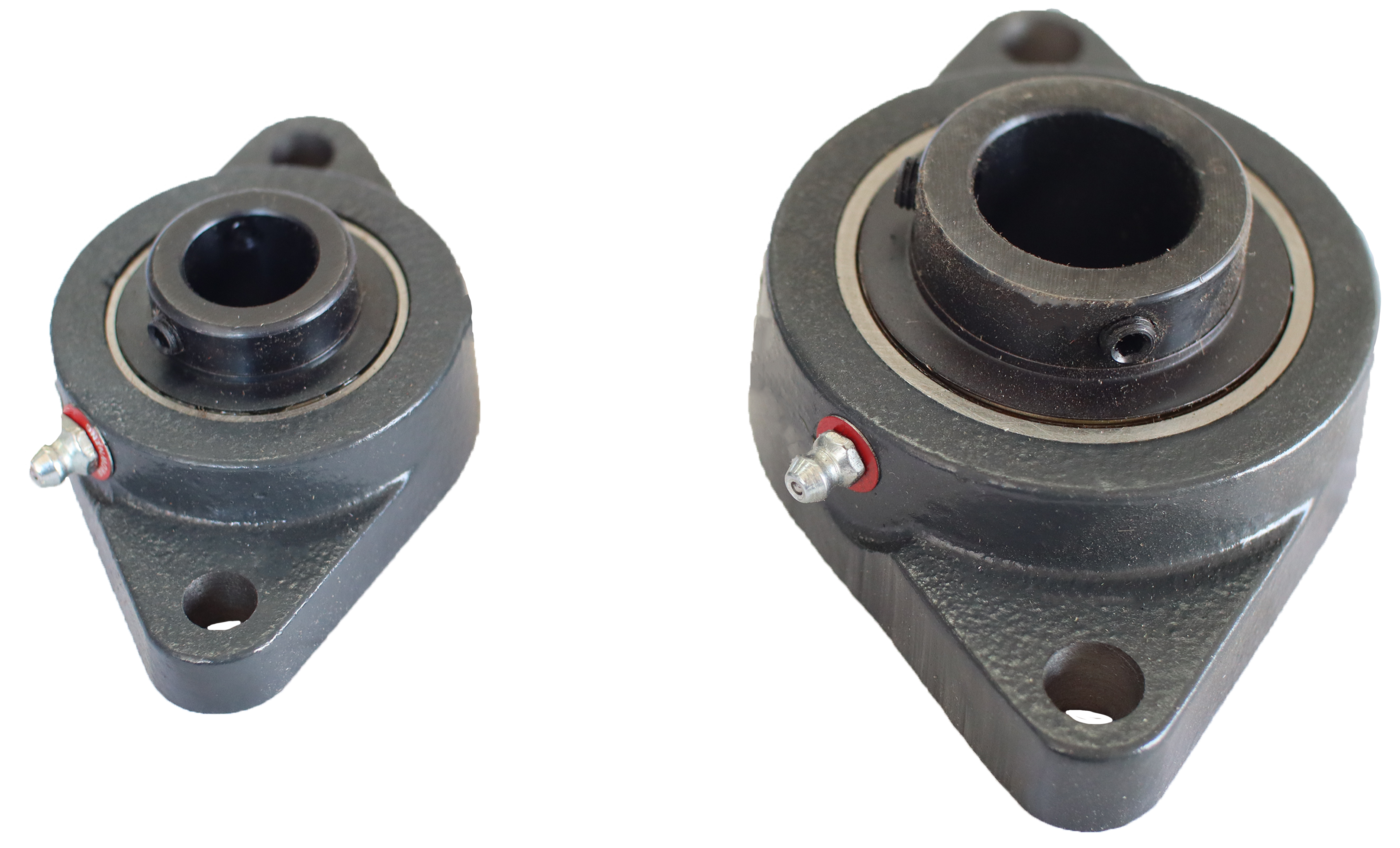

Bearings

Supports each end of the roller/shaft, allowing the rollers to rotate smoothly.

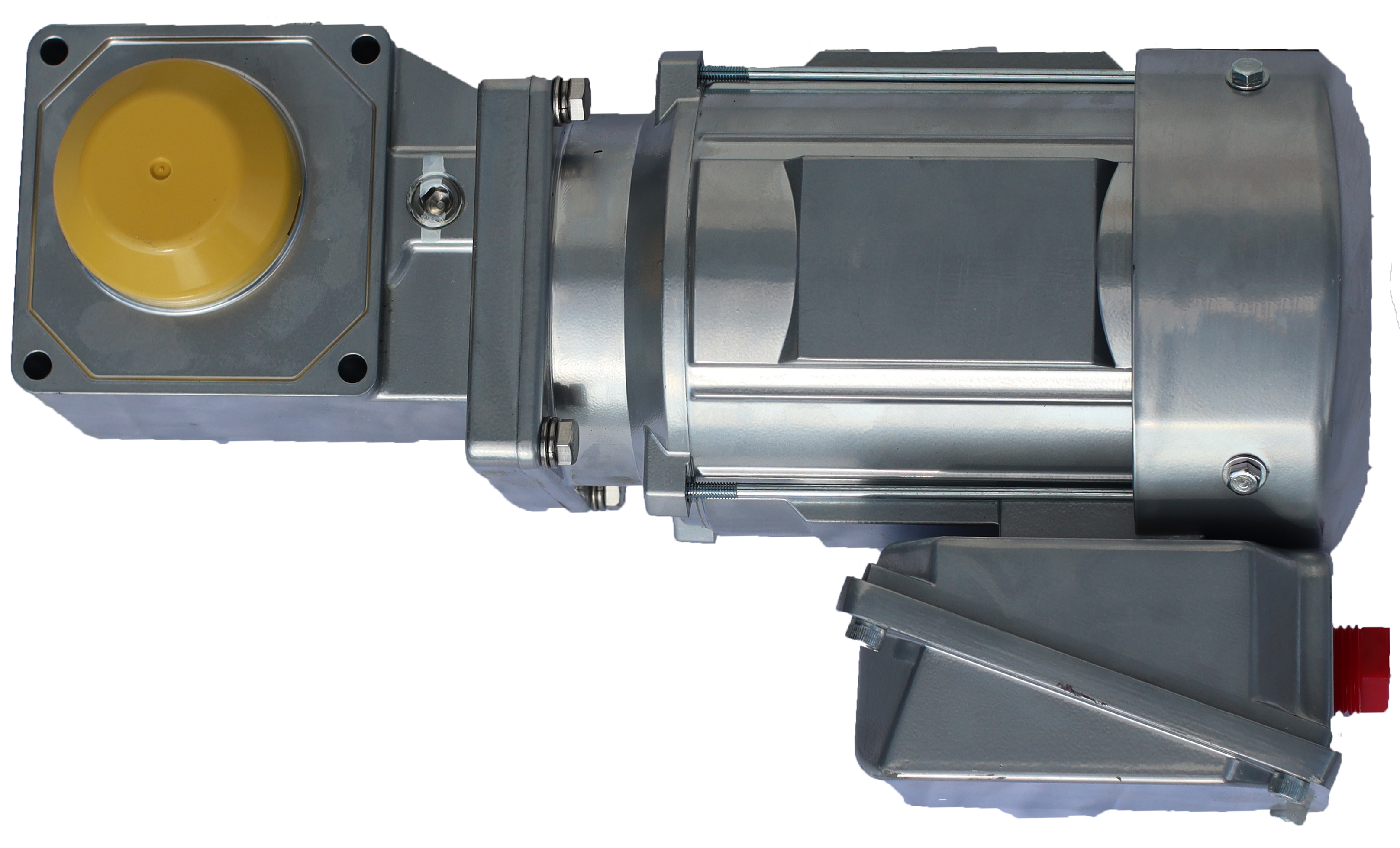

Gearbox

Speeds or slows down the conveyor´s rotating components by controlling the amount of torque that is delivered.

Reducer

Controls the amount of output speed from a motor by the torque delivered to the roller/shaft

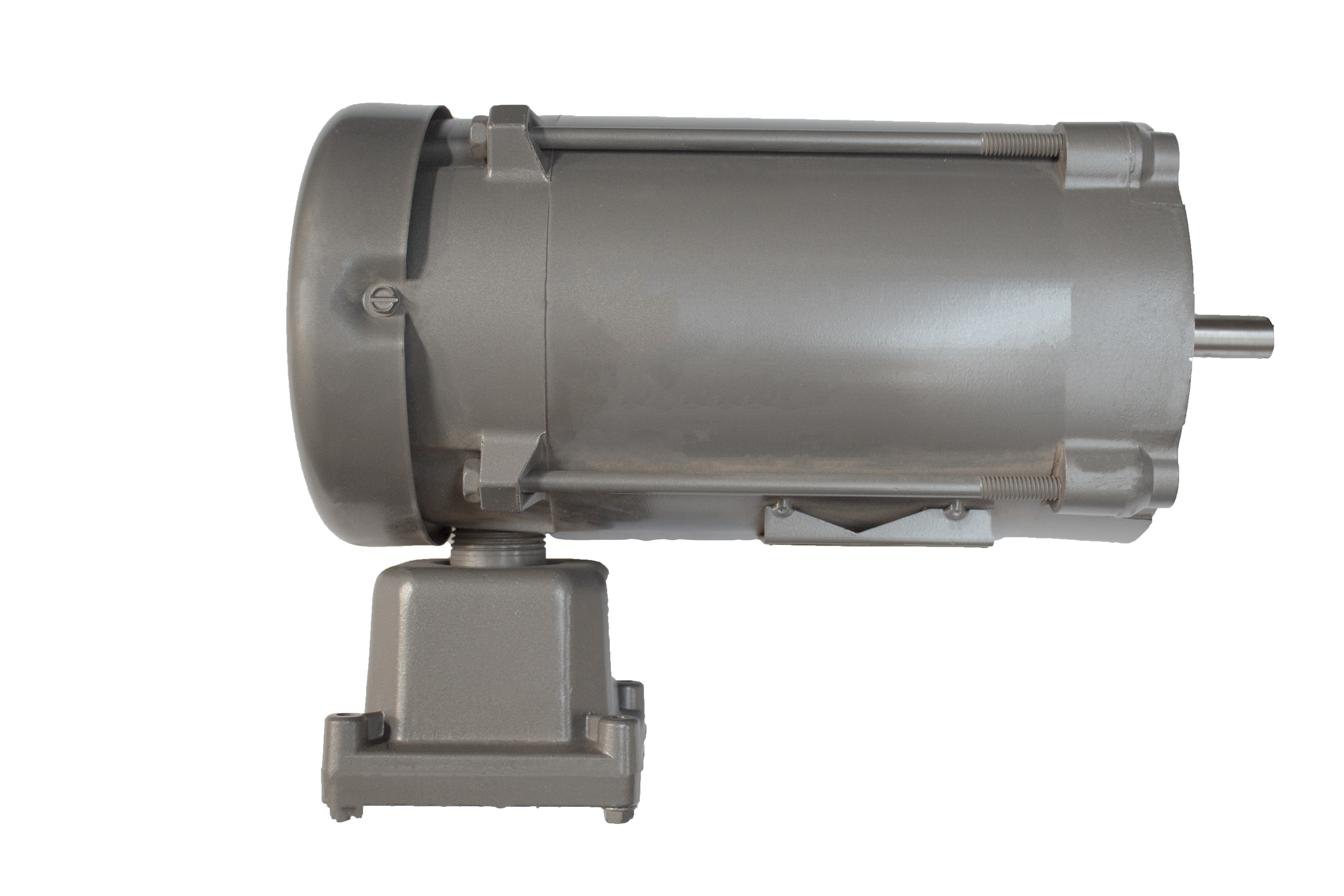

Motor

Provides the power needed to operate the conveyor.

Collars

Component to fix the gear box to the roller shaft ensuring a smooth, slip-free rotation and efficient belt movement.

Sprockets

Crucial component in the transmission of rotation between the shaft and the belt.

Cleats

A horizontal part added to the belt that helps move parts through inclined and declined conveyors as well as provide consistent spacing between products.

Sensors

Help monitor and control the movement, speed, position and condition of the parts and equipment.

Stainless steel covers

Ensures operational safety and hygiene of the handling equipment and the material to be conveyed.

UHMW slices and blocks

Provides smooth support for the conveyor belt, reducing friction and wear.

Control Panel

The assembly of electronic and electric devises that together are used to monitor, control and coordinate all pneumatic, electronic and mechanic parts in a handling system operation.

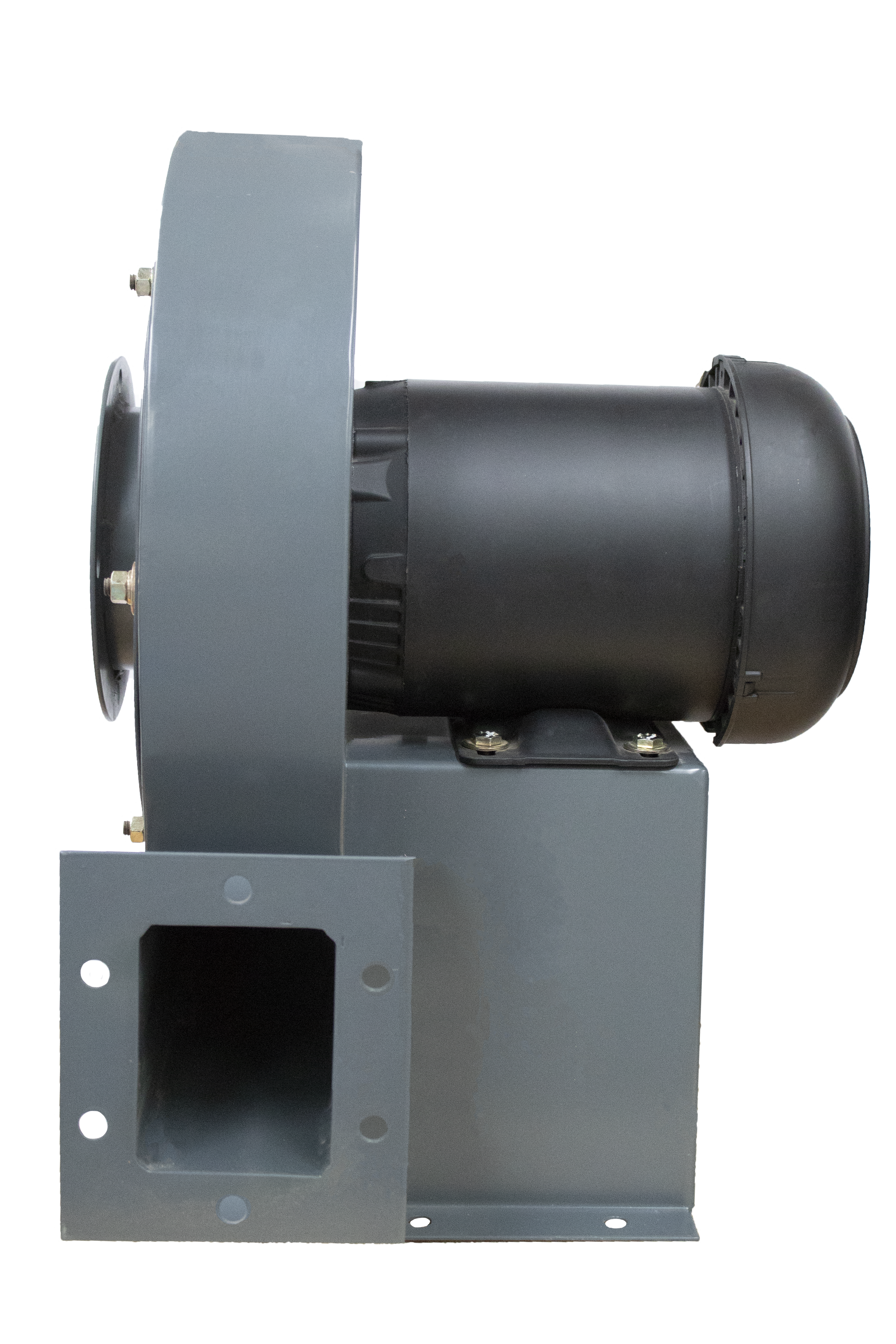

Blower

Used in pneumatic conveying systems, these components are used to move parts through tubes, preventing blockages and ensuring a constant flow of parts.

Sight Glass

A tube in a pneumatic conveying system, made out of see through material that allows visual observation of the part flow within the tube.

Compression coupling

A fixation joint that allows for the union of two tubes in a pneumatic conveying system.

Butyrate Pipe

A transparent and rigid tube used to convey parts pneumatically.

Stainless steel pipe

A stainless steel rigid tube used to convey parts pneumatically.

Pneumatics

A variety of components that are run on compressed air to move an actuator.

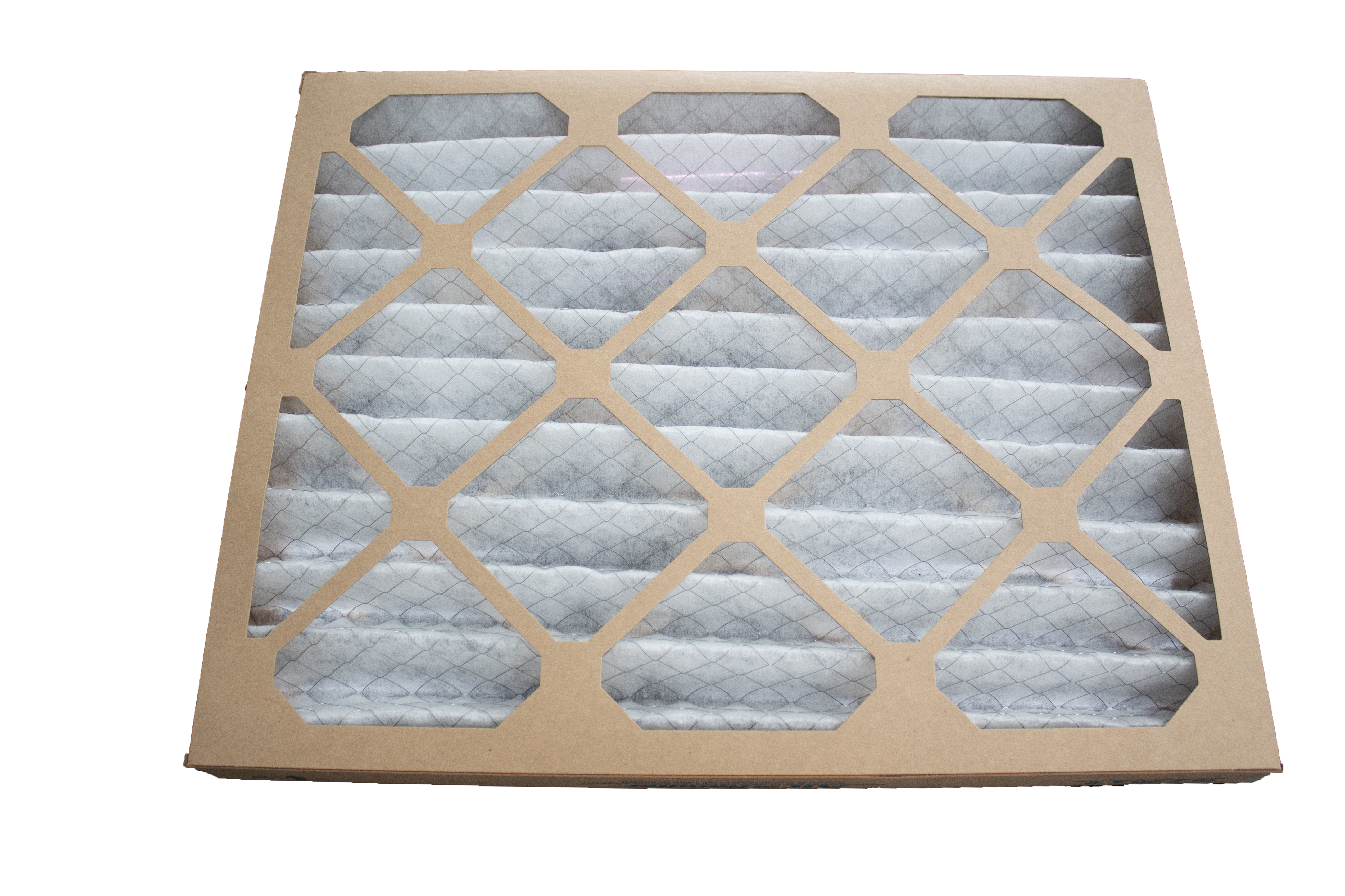

Filters

Remove contaminants, moisture and other particles from compressed air or the environment that could travel into the conveying system

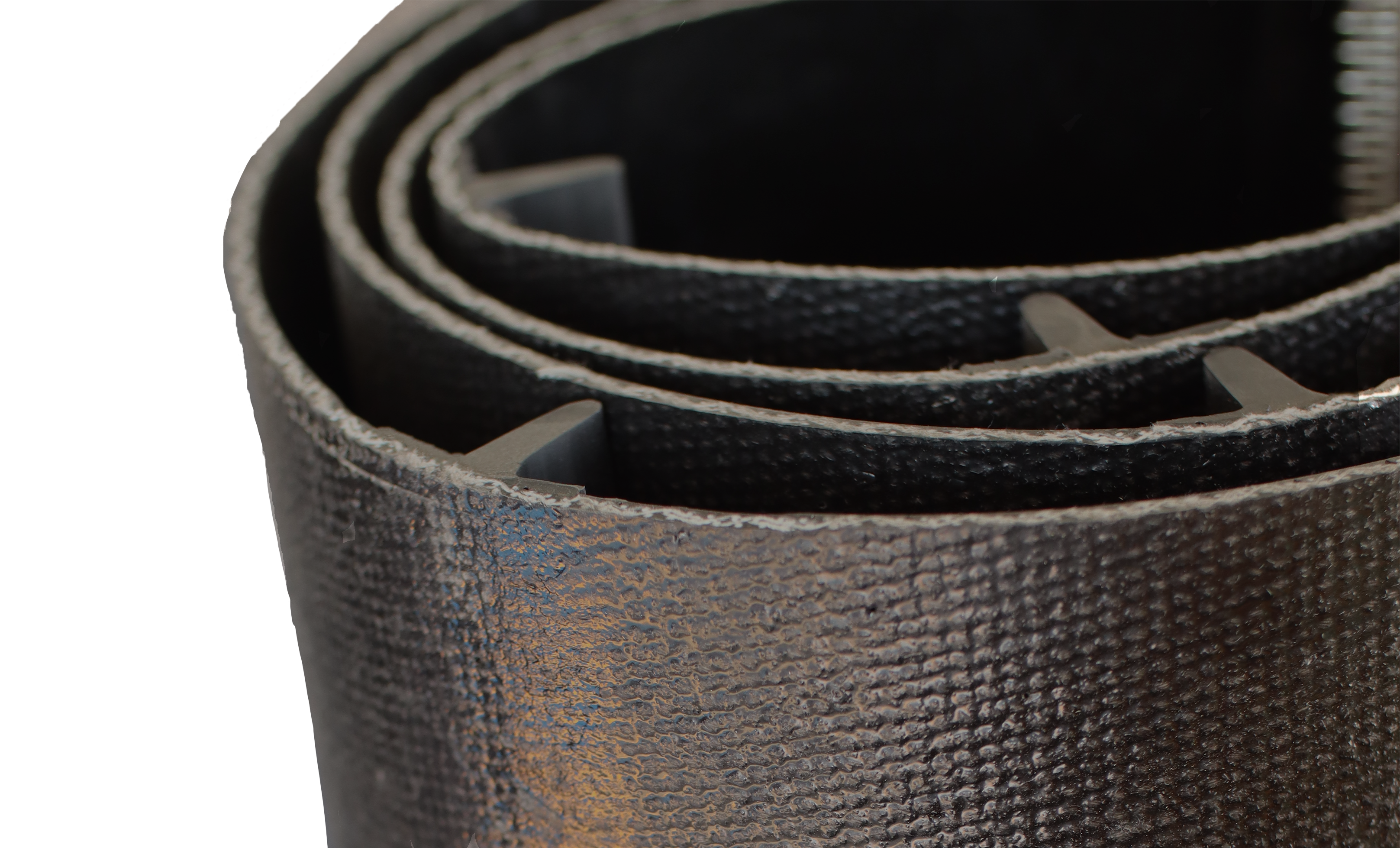

PVC Belt

Conveyor component that is wrapped around two rollers and driven by a motor, parts rest on the belt when moved from one end of the conveyor to the other.

Motorized Roller

AC motorized conveyor roller comes equipped with a 230V AC brushless motor inside each roller’s tube.

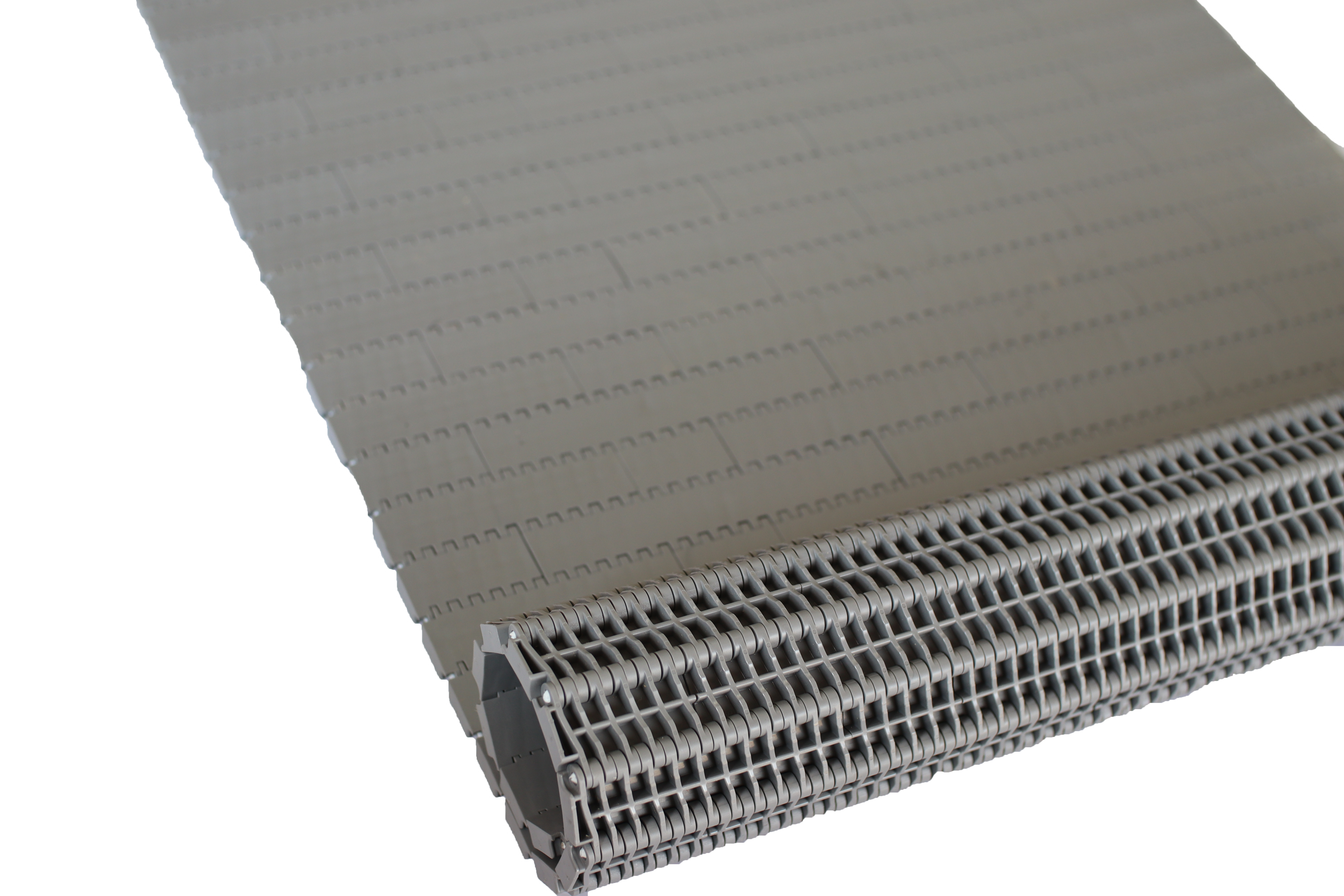

Intralox Belt

Conveyor component that is wrapped around two rollers and driven by a motor, parts rest on the belt when moved from one end of the conveyor to the other.